The Carrier WeatherMaker 9200 is a high-efficiency HVAC system designed for reliable performance. This guide provides essential insights into its electrical requirements for safe and efficient installation.

1.1 Overview of the WeatherMaker 9200 Series

The Carrier WeatherMaker 9200 series is a line of high-efficiency heating and cooling systems designed for residential and light commercial use. Known for their energy efficiency and advanced technology, these units are built to provide reliable performance and comfort. The series includes various models with different capacities and configurations, ensuring flexibility for diverse installation needs. With a focus on reducing energy consumption and operational noise, the WeatherMaker 9200 series is a popular choice for modern HVAC requirements. Proper electrical setup is crucial to ensure optimal performance, safety, and compliance with industry standards, making the electrical requirements document an essential resource for installers and technicians.

1.2 Importance of Understanding Electrical Requirements

Understanding the electrical requirements of the Carrier WeatherMaker 9200 is crucial for ensuring safe, efficient, and compliant installation. Proper electrical setup prevents hazards, optimizes performance, and guarantees system longevity. It also ensures compliance with local and national codes, avoiding potential legal issues. Incorrect wiring or insufficient power supply can lead to malfunctions, safety risks, or even void the warranty. By adhering to the specified electrical guidelines, installers can maintain reliability, reduce energy consumption, and uphold safety standards. This knowledge is essential for technicians and installers to configure the system correctly and avoid costly errors or downtime.

Understanding the Electrical Requirements Document

This document serves as a comprehensive guide for installers, outlining the electrical needs of the WeatherMaker 9200, ensuring a safe and proper system setup and operation.

2.1 What is the Carrier WeatherMaker 9200 Electrical Requirements PDF?

The Carrier WeatherMaker 9200 Electrical Requirements PDF is an official document published by Carrier, detailing the electrical specifications and guidelines for the WeatherMaker 9200 HVAC system. It provides essential information for installers, technicians, and contractors to ensure proper electrical connections, safety, and compliance with local and national codes. The document includes voltage requirements, current ratings, wiring diagrams, and safety protocols to facilitate a smooth and efficient installation process. This resource is crucial for ensuring the system operates at its peak performance while adhering to all relevant electrical standards and regulations. By following the guidelines outlined in this PDF, professionals can guarantee a safe and reliable setup.

2.2 Key Sections of the Document

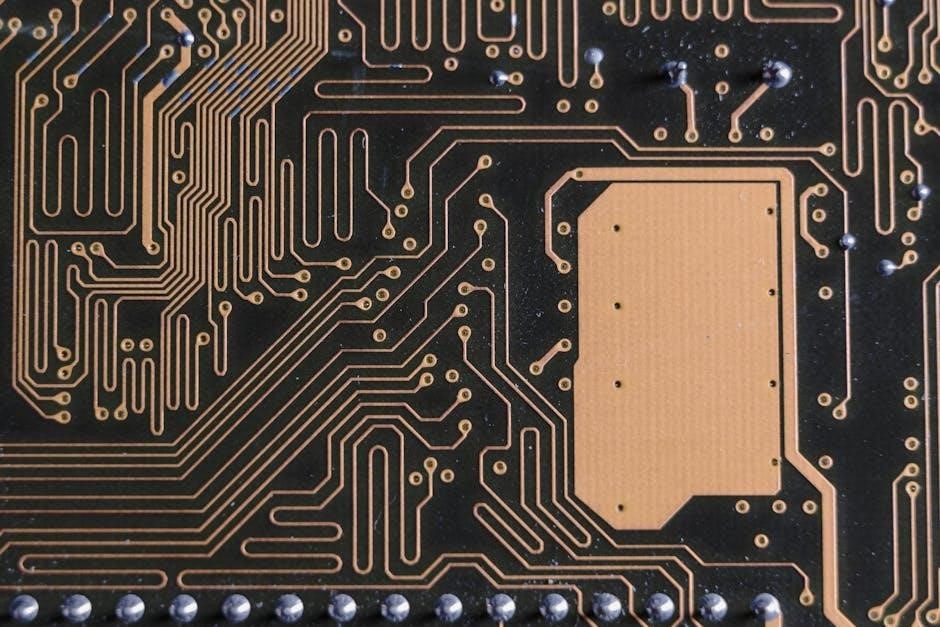

The Carrier WeatherMaker 9200 Electrical Requirements PDF is organized into clear sections for easy reference. It begins with technical specifications, detailing voltage, current, and phase requirements. Next, it outlines installation guidelines, including circuit sizing and grounding. Safety precautions are emphasized, covering proper handling of electrical components and emergency procedures. Finally, compliance with local and national codes is addressed to ensure legal and safe installation. Each section is designed to provide comprehensive information, making it an indispensable resource for installers and technicians. Proper understanding of these sections ensures a safe and efficient setup of the HVAC system.

Electrical Specifications of the WeatherMaker 9200

The Carrier WeatherMaker 9200’s electrical specifications are crucial for proper installation and operation. They outline the unit’s power requirements, efficiency ratings, and compliance with safety standards.

3.1 Voltage and Current Requirements

The Carrier WeatherMaker 9200 operates within specific voltage and current ranges to ensure optimal performance. The system typically requires a voltage supply of 208-230V for single-phase models and 460V for three-phase configurations. Current requirements vary depending on the unit’s capacity and operational mode. Proper sizing of the electrical supply ensures safe and efficient operation. It is crucial to refer to the Electrical Requirements PDF for exact specifications, as mismatched voltage or current can lead to system malfunctions or safety hazards. Always verify the unit’s nameplate data and consult local electrical codes for compliance. Correct voltage and current configuration are essential for reliable operation and longevity of the system.

3.2 Power Consumption and Ratings

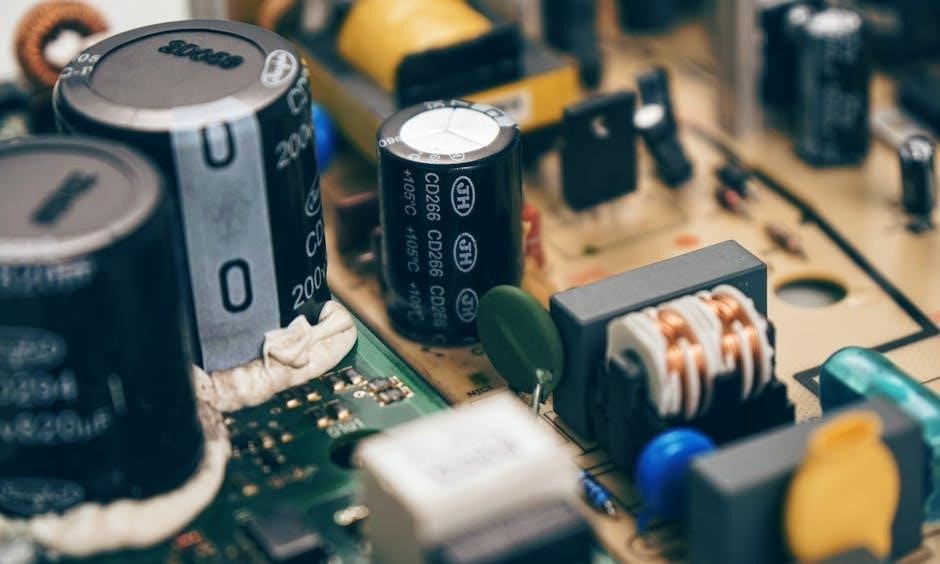

The Carrier WeatherMaker 9200’s power consumption and ratings are essential for proper installation and operation. These specifications ensure the system operates within designated limits, maintaining efficiency and safety. The unit’s power consumption varies based on operating conditions, such as heating, cooling, and fan-only modes. Carrier provides detailed ratings, including maximum power input, output, and efficiency ratings like AFUE and SEER. Adhering to these ratings is crucial for optimal performance and to meet local electrical codes. If unsure, consult a licensed HVAC technician. Always refer to the Carrier WeatherMaker 9200 Electrical Requirements PDF for precise specifications tailored to your model and application.

3.3 Phase and Frequency Requirements

The Carrier WeatherMaker 9200 operates on specific phase and frequency configurations to ensure optimal performance. It is designed for use with single-phase or three-phase electrical supplies, depending on the model. The system typically requires a 60 Hz frequency, which is standard in most residential and commercial electrical systems in the U.S. Proper phase and frequency alignment is critical to avoid motor damage, overheating, or reduced efficiency. Mismatched phase or frequency settings can lead to operational issues, so it is essential to verify these specifications during installation. Always refer to the unit’s rating plate or the Electrical Requirements PDF for accurate phase and frequency details to ensure safe and efficient operation.

Circuit Requirements for Installation

Proper circuit requirements ensure the WeatherMaker 9200 operates efficiently and safely. This section outlines key considerations for electrical setup to meet performance and safety standards effectively.

4.1 Circuit Sizing and Capacity

Proper circuit sizing is critical for the WeatherMaker 9200 to operate efficiently and safely. The system requires a dedicated circuit to handle its electrical load without interference. Factors such as voltage, current, and maximum load must be considered to ensure the circuit can manage peak demand. Undersized circuits may lead to overheating or insufficient power, while oversized circuits can be inefficient. Always refer to the Electrical Requirements PDF for specific sizing recommendations tailored to the unit’s configuration. Correct wire gauge and circuit breaker size are also essential to prevent electrical hazards and ensure reliable performance over time. This step is vital for both safety and system longevity.

4.2 Recommended Circuit Type and Configuration

The WeatherMaker 9200 requires a dedicated circuit to ensure optimal performance. A 120V or 240V circuit, depending on the model, is recommended to prevent voltage drops. Use a circuit breaker or fuse-rated for the unit’s maximum current. The wiring gauge should match the system’s power requirements to minimize resistance. A single-pole breaker is sufficient for single-phase units, while three-phase models need a three-pole breaker. Proper grounding is essential for safety. Ensure the circuit is exclusively for the HVAC system to avoid interference. Always consult local codes and the Electrical Requirements PDF for specific configurations tailored to your region and system specifications.

4.3 Circuit Protection Devices (Fuses, Breakers)

Proper circuit protection is crucial for the Carrier WeatherMaker 9200 to prevent damage from overcurrent or short circuits. Fuses and circuit breakers act as safety barriers, interrupting power when faults occur. Ensure devices are rated for the system’s voltage and current requirements. Selecting the correct fuse or breaker size is vital to avoid nuisance tripping while providing adequate protection. Use only UL-listed or equivalent devices for compliance and reliability. Regularly inspect these components to ensure they are functioning correctly. Always refer to the WeatherMaker 9200 Electrical Requirements PDF for specific recommendations on circuit protection devices to maintain system integrity and safety standards.

Installation Guidelines

Proper installation ensures optimal performance and safety. Plan carefully, use appropriate tools, follow safety protocols, and ensure compliance with all electrical codes and manufacturer guidelines.

5.1 Pre-Installation Electrical Checks

Before installing the WeatherMaker 9200, verify the electrical supply matches the unit’s specifications. Ensure proper grounding, circuit integrity, and sufficient voltage. Check for any damage to wires or connectors. Use a multimeter to confirm voltage and phase balance. Verify circuit breakers or fuses are appropriately rated. Ensure all electrical components are compatible and meet local codes. Conduct a power quality assessment if necessary. Consult the Electrical Requirements PDF for specific guidelines. Proper preparation ensures a safe and efficient installation process, minimizing risks of electrical issues or system malfunction. Always follow safety protocols and manufacturer recommendations for pre-installation checks.

5.2 Connecting the WeatherMaker 9200 to the Electrical Supply

Connecting the WeatherMaker 9200 to the electrical supply requires careful adherence to the specified voltage, current, and power ratings. Ensure the electrical supply matches the unit’s requirements, as outlined in the Electrical Requirements Document. Verify the voltage rating and phase configuration before proceeding. Properly size and connect the wires to avoid overheating or power issues. Use appropriate connectors and ensure all connections are secure and meet local electrical codes. Always disconnect the power supply before servicing or installing the unit. Grounding must be correctly implemented to ensure safety. Consult a licensed electrician if unsure about any step to prevent potential hazards. Compliance with safety standards is essential for reliable operation.

5.3 Grounding Requirements for Safety

Proper grounding is critical for the safe operation of the Carrier WeatherMaker 9200. Ensure all electrical components are connected to an earth ground to prevent voltage surges and electrical shocks. Use approved grounding methods, such as a grounding rod or metallic water piping, to create a safe path for fault currents. Verify that all grounding connections are secure and free from corrosion. Improper grounding can lead to equipment damage, fire hazards, or injury. Always adhere to local electrical codes and the National Electric Code (NEC) for grounding requirements. Regularly inspect grounding systems to ensure compliance and safety standards are maintained.

Safety Considerations

Ensuring safety is critical when handling electrical systems. Always follow voltage ratings, use proper tools, and wear protective gear to prevent accidents and electrical shocks.

6.1 General Safety Precautions

Always disconnect power before servicing the WeatherMaker 9200. Wear protective gear, including gloves and safety glasses, to prevent injury. Ensure proper ventilation to avoid gas exposure. Never overload circuits, as this can cause electrical fires. Keep loose clothing and long hair tied back to avoid entanglement with moving parts. Avoid working in damp conditions to reduce shock risks. Use insulated tools to handle live components safely. Familiarize yourself with emergency shutdown procedures. Adhere to all local safety codes and manufacturer guidelines to ensure safe operation and maintenance of the system. Neglecting these precautions can lead to serious injury or equipment damage.

6.2 Handling Electrical Components Safely

Handling electrical components of the Carrier WeatherMaker 9200 requires utmost care to ensure safety and prevent damage. Always disconnect the power supply before servicing or installing components.

- Use insulated tools to avoid direct contact with live electrical parts.

- Avoid damaging wires, terminals, or connectors, as this can lead to system malfunctions.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Ensure all components are properly grounded to prevent electrical shocks.

- Follow the manufacturer’s instructions and safety guidelines meticulously.

Proper handling ensures the system operates efficiently and safely, reducing the risk of electrical hazards.

Troubleshooting Electrical Issues

Identify common electrical problems like power outages or blown fuses. Check connections, circuit breakers, and wiring for faults. Consult the manual for diagnostic steps and solutions.

7.1 Common Electrical Issues and Solutions

Common electrical issues with the WeatherMaker 9200 include power outages, blown fuses, and tripped breakers. These often result from overloaded circuits or improper wiring. Solutions involve resetting breakers, replacing fuses, or upgrading circuit capacity. Additionally, voltage fluctuations can cause malfunctions; ensure the supply matches the unit’s requirements. Loose connections may also disrupt operation, so tightening wires is essential. If issues persist, consult the electrical requirements document or contact a licensed electrician to address complex problems and prevent further complications.

7.2 Diagnosing Power Supply Problems

Diagnosing power supply issues in the WeatherMaker 9200 involves checking voltage levels, ensuring proper electrical connections, and verifying phase balance. Use a multimeter to measure voltage at the terminal block. If voltage is incorrect, inspect the circuit for breaks or short circuits. Check for loose connections or corrosion, which can disrupt power flow. Verify that the system is receiving the correct phase and frequency as specified in the electrical requirements. Electrical noise or interference can also cause malfunctions. Use an oscilloscope to detect anomalies in the power supply. Always refer to Carrier’s troubleshooting guide for detailed procedures and ensure all diagnostics align with safety standards.

Compliance and Regulations

Ensure the WeatherMaker 9200 installation meets local and national electrical codes. Adherence to safety standards guarantees compliance and optimal system performance while minimizing risks.

8.1 Local and National Electrical Codes

Compliance with local and national electrical codes is crucial for the safe and legal installation of the Carrier WeatherMaker 9200. These codes, such as the National Electric Code (NEC), outline specific requirements for voltage, current, and grounding. Adhering to these standards ensures the system operates efficiently and safely. Failure to comply can result in legal penalties, safety hazards, or system malfunction. Always consult local authorities to verify code requirements and ensure installations meet all regulations. This step is essential for avoiding potential risks and guaranteeing the system’s reliability and performance over time.

8.2 Compliance with Safety Standards

Compliance with safety standards is critical for the Carrier WeatherMaker 9200 to ensure safe and reliable operation. The system adheres to regulations set by organizations like UL (Underwriters Laboratories) and NEC (National Electric Code). These standards address electrical safety, fire prevention, and performance consistency. Proper installation and maintenance are essential to meet these requirements. Failure to comply could result in hazards or system malfunctions. Always refer to the Carrier WeatherMaker 9200 Electrical Requirements PDF for specific guidelines. Adhering to these standards ensures the system operates safely and efficiently, protecting both users and property. Regular inspections are recommended to maintain compliance and optimal performance.

Proper electrical installation ensures optimal performance and safety. Adhering to guidelines and compliance with safety standards is crucial for reliable operation and long-term efficiency.

9.1 Summary of Key Points

The Carrier WeatherMaker 9200 requires precise electrical setup for optimal performance. Key considerations include voltage, current, and phase alignment, as well as circuit sizing and grounding. Compliance with local and national codes ensures safety and efficiency. Proper installation practices, such as using the right circuit protection devices, prevent electrical hazards. Regular maintenance and adherence to safety standards are essential for long-term reliability. Understanding and following the guidelines in the Electrical Requirements PDF is crucial for installers to achieve a safe and efficient system operation.

9.2 Final Thoughts on Proper Electrical Installation

Proper electrical installation is critical for the safe and efficient operation of the Carrier WeatherMaker 9200. Ensuring compliance with the specified requirements and local codes guarantees optimal performance, energy efficiency, and system longevity. Neglecting these guidelines can lead to safety hazards, reduced system lifespan, and increased energy costs. Always refer to the Electrical Requirements PDF for detailed specifications and follow best practices for a secure and reliable setup. By prioritizing correct installation, you ensure the system operates as intended, providing consistent heating and cooling while maintaining safety standards. Regular maintenance and inspections are also essential to uphold performance and safety over time.