Warehouse racking systems are critical for efficient storage and operations. Safety standards ensure structural integrity, prevent hazards, and protect personnel, contributing to operational efficiency and regulatory compliance.

1.1 Overview of Warehouse Racking Systems

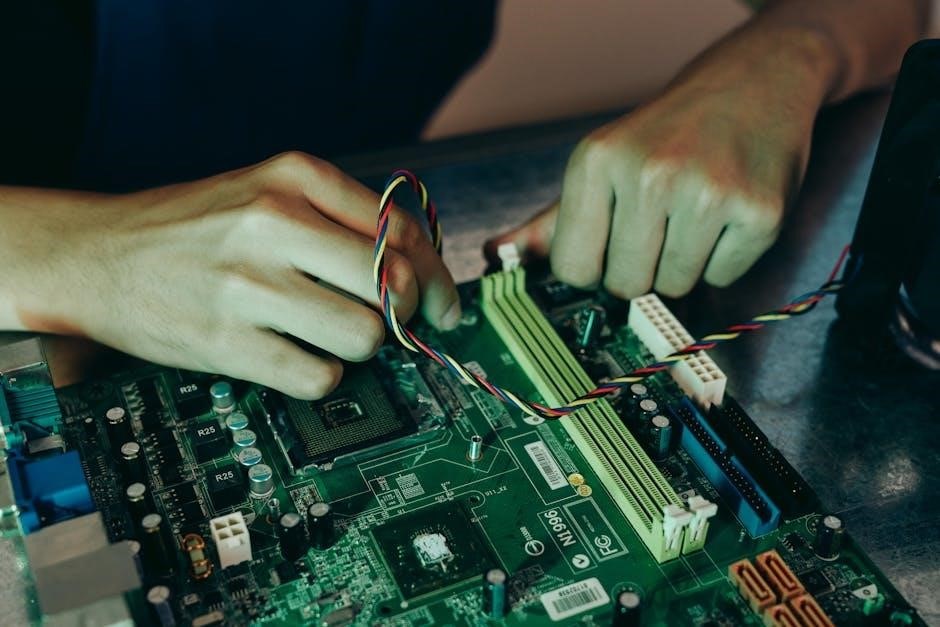

Warehouse racking systems are essential for optimizing space and efficiency in storage facilities. They consist of structures like beams, uprights, and connectors, designed to hold various loads. Pallet racking, cantilever racking, and shelving are common types, each suited for specific materials. Proper installation and maintenance ensure stability and safety, while components like safety clips and pins enhance durability. These systems are tailored to meet operational needs, ensuring smooth workflow and inventory management. Their design and configuration directly impact warehouse productivity and safety standards.

1.2 Importance of Safety in Warehouse Operations

Safety is paramount in warehouse operations to protect employees, equipment, and inventory. Accidents, such as racking collapses, can lead to injuries and financial losses. Adhering to safety standards minimizes risks and ensures compliance with regulations. Proper training, regular inspections, and maintenance of racking systems are vital. A safe environment fosters productivity, reduces downtime, and enhances overall efficiency. Prioritizing safety also mitigates legal liabilities and promotes a culture of responsibility among warehouse staff, making it a cornerstone of sustainable operations.

Key International and Regional Safety Standards

International safety standards, such as European EN 15620, U.S. OSHA regulations, and Australian AS 4084, provide guidelines to ensure safe racking system design and installation globally.

2.1 European Standards (EN 15620, EN 15635)

European standards EN 15620 and EN 15635 outline specific requirements for the design, testing, and use of steel storage pallet racking systems. These standards ensure structural integrity, safety, and durability. They cover load capacities, material specifications, and installation guidelines. Compliance with these standards is mandatory in Europe to safeguard against risks and ensure reliable performance. By adhering to EN standards, warehouses can maintain a safe working environment and meet legal obligations effectively.

2.2 OSHA Regulations in the United States

OSHA regulations in the U.S; set strict safety standards for warehouse racking systems to ensure worker safety and prevent accidents. Employers must comply with guidelines on load capacities, proper installation, and regular inspections. OSHA requires racking systems to be designed and maintained according to manufacturer specifications and industry standards. Safety measures include securing beams with clips or pins and ensuring uprights are protected from damage. Employers are also mandated to train employees on racking safety and conduct periodic inspections to maintain compliance and prevent hazards.

2.3 Australian Standards (AS 4084)

The Australian Standard AS 4084 provides guidelines for the design, installation, and maintenance of steel storage racking systems. It ensures compliance with safety requirements, focusing on load capacity calculations, material quality, and structural integrity. The standard emphasizes protection of racking from damage and mandates regular inspections to identify hazards. Employers must adhere to AS 4084 to ensure a safe working environment, aligning with regulatory obligations and industry best practices for warehouse operations in Australia.

Inspection Guidelines for Racking Systems

Regular inspections are essential to identify damage and ensure racking systems operate safely. Trained personnel should conduct checks, focusing on structural integrity and load-bearing capacity.

3.1 Frequency of Inspections

Inspections of racking systems should be conducted regularly to ensure safety and compliance. High-traffic areas require more frequent checks, while lower-traffic areas may need inspections every 6-12 months. Additionally, after any significant event, such as an earthquake or equipment collision, an immediate inspection is necessary. Trained professionals should perform these evaluations to identify potential hazards and ensure the system remains structurally sound. Regular inspections help prevent accidents and extend the lifespan of the racking system.

3.2 Checklist for Racking Inspection

A detailed checklist is essential for racking inspections to ensure safety and compliance. Key items include checking for damage, loose bolts, and beam misalignment. Verify uprights for dents or corrosion, and ensure safety clips are securely in place. Inspect load-bearing components for signs of wear and confirm all racks are level. Document any damage or defects and address them promptly. This systematic approach helps identify potential hazards and ensures the racking system remains safe and functional for warehouse operations;

Maintenance and Repair Best Practices

Regular inspections and preventative maintenance are vital. Address damage promptly, follow manufacturer guidelines, and ensure repairs meet safety standards to prevent system failure and ensure compliance.

4.1 Regular Maintenance Requirements

Regular maintenance ensures racking systems remain stable and secure. Inspect for damage, wear, and tear monthly. Check bolts, connectors, and frames. Address issues promptly to prevent structural compromise. Follow manufacturer guidelines for lubrication and part replacement. Train staff to identify hazards and report concerns. Document all maintenance activities for compliance and accountability. Routine checks prevent costly repairs and enhance workplace safety, ensuring optimal functionality and longevity of the racking system.

4.2 Emergency Repairs and Safety Protocols

In case of damage or instability, immediate action is required. Assess the situation to prevent further damage or collapse. Isolate the affected area and restrict access until repairs are made. Contact certified professionals to evaluate and repair the racking system. Temporary supports may be necessary to stabilize the structure. Ensure all safety protocols, such as evacuating the area and using safety equipment, are followed. Document the incident and repairs for future reference and compliance with safety standards.

Training and Employee Education

Comprehensive training programs ensure staff understand racking safety, proper PPE use, and emergency protocols. Regular updates and hands-on sessions maintain awareness and compliance with safety standards.

5.1 PPE Selection and Use

Proper selection and use of Personal Protective Equipment (PPE) are crucial for warehouse safety. Hard hats, safety glasses, gloves, and steel-toe boots protect workers during racking inspections and maintenance. Employers must ensure PPE is readily available and staff are trained in its correct use. Regular checks guarantee equipment is in good condition. Adherence to PPE protocols minimizes injury risks, ensuring compliance with safety standards and fostering a culture of workplace safety and responsibility.

5.2 Safety Training Programs for Warehouse Staff

Comprehensive safety training programs are essential for warehouse staff to ensure awareness of potential hazards and proper handling of racking systems. Training should cover hazard identification, emergency protocols, and the correct use of PPE. Forklift operators and personnel involved in racking inspections require specialized training. Regular updates and refreshers ensure compliance with evolving safety standards. Employers must document all training activities and ensure participation from all relevant staff, fostering a culture of safety and accountability in daily operations.

Compliance and Regulatory Requirements

Adhering to local and international safety standards ensures legal compliance, mitigates risks, and protects workers. Employers must meet regulations like OSHA, EN, and AS standards for racking systems.

6.1 Legal Obligations for Employers

Employers are legally required to ensure warehouse racking systems comply with safety standards to protect workers and prevent accidents. They must adhere to regulations like OSHA, EN, and AS standards, conducting regular inspections and maintenance. Employers are also responsible for providing proper training and personal protective equipment (PPE) to employees. Failure to meet these obligations can result in legal penalties and increased workplace risks. Compliance ensures a safe working environment and minimizes liability, aligning with both regulatory and moral responsibilities to safeguard personnel and operational integrity.

6.2 Documentation and Record-Keeping

Accurate documentation and record-keeping are essential for compliance with warehouse racking safety standards. Employers must maintain detailed records of inspections, maintenance, and repairs, ensuring all activities align with regulatory requirements; Training records, inspection checklists, and incident reports should also be preserved. Proper documentation not only facilitates audits but also demonstrates commitment to safety and accountability. It ensures transparency, traceability, and adherence to legal and industry standards, minimizing risks and enhancing overall operational integrity and responsibility.

Best Practices for Racking Installation

Ensure racking systems are installed by competent suppliers or manufacturers, adhering to industry standards like EN 15620. Proper planning, precise measurements, and manufacturer guidelines are essential for safety and compliance.

7.1 Role of Competent Suppliers and Manufacturers

Competent suppliers and manufacturers play a crucial role in ensuring racking systems meet safety standards. They design and supply systems compliant with regulations like EN 15620. Proper installation by qualified professionals is essential to avoid structural weaknesses. Manufacturers provide guidelines for load capacity and maintenance, ensuring durability and safety. Their expertise guarantees that racking systems are tailored to specific warehouse needs, minimizing risks and ensuring compliance with industry norms. Regular training and support from manufacturers further enhance system reliability and operational safety.

7.2 Ensuring Compliance During Installation

Ensuring compliance during racking installation involves adhering to international and regional standards. Installations must follow manufacturer guidelines and load capacity specifications. Supervision by qualified professionals is essential to prevent structural weaknesses. Compliance checks include verifying all safety clips and bolts are securely fastened. Documentation of the installation process ensures accountability and traceability. Regular audits during installation help identify and rectify potential issues early, ensuring the system meets safety standards and regulatory requirements from the outset.