Hydraulic fittings are essential components in fluid power systems‚ ensuring reliable connections for hoses‚ tubes‚ and pipes. They adhere to standards like SAE and ISO for optimal performance and safety.

1.1 Importance of Hydraulic Fittings in Fluid Power Systems

Hydraulic fittings are critical for maintaining pressure integrity and ensuring reliable fluid flow in hydraulic systems. They prevent leaks‚ reduce downtime‚ and enhance system performance. Adhering to standards like SAE J514 and J516‚ these fittings are essential for safe and efficient operation in industrial and mobile applications.

1.2 Overview of Hydraulic Fittings Types and Standards

Hydraulic fittings come in various types‚ including NPT‚ JIC‚ BSPP‚ and ORFS‚ each designed for specific applications. They adhere to standards like SAE and ISO‚ ensuring compatibility and performance. These fittings feature threaded or flared connections‚ designed to maintain system integrity‚ prevent leaks‚ and optimize fluid flow efficiency in hydraulic systems.

Common Types of Hydraulic Fittings

Common hydraulic fittings include NPT‚ JIC‚ BSPP‚ and ORFS types‚ each designed for specific applications‚ ensuring secure connections and efficient fluid flow in hydraulic systems.

2.1 NPT (National Pipe Tapered) Fittings

NPT (National Pipe Tapered) fittings are a staple in U.S. fluid and gas transfer systems‚ featuring tapered threads that create a tight seal when properly threaded. Used extensively for over 100 years‚ they are known for their reliability and sealing capabilities‚ making them ideal for various hydraulic and pneumatic applications.

2.2 JIC (37° Flared) Fittings

JIC (37° Flared) fittings are widely used in hydraulic systems due to their reliable sealing capabilities and resistance to pressure and vibration. Featuring a 37-degree flared connection‚ these fittings are ideal for high-performance applications. Their durability and ease of assembly make them a popular choice in industrial and mobile hydraulic systems.

2.3 BSPP (British Standard Pipe Parallel) Fittings

BSPP (British Standard Pipe Parallel) fittings are widely used in hydraulic systems‚ featuring parallel threads and a straight connection. They rely on O-rings or gaskets for sealing‚ ensuring leak-free performance. Common in British and European applications‚ BSPP fittings are durable and versatile‚ suitable for various pressure ranges and fluid types in industrial settings.

2.4 ORFS (O-Ring Face Seal) Fittings

ORFS (O-Ring Face Seal) fittings feature a flat face with an O-ring for a leak-tight seal‚ ideal for high-pressure applications. They eliminate the need for additional gaskets or washers‚ ensuring reliability in demanding environments. Commonly used in aerospace‚ defense‚ and industrial systems‚ ORFS fittings provide a secure‚ leak-resistant connection‚ making them a preferred choice for critical hydraulic systems.

Hydraulic Fittings Standards and Specifications

Hydraulic fittings adhere to strict standards like SAE and ISO‚ ensuring safety‚ compatibility‚ and performance. These specifications guide procurement and system integration‚ guaranteeing fittings meet pressure and durability requirements.

3.1 SAE Standards for Hydraulic Fittings

SAE standards‚ such as SAE J514 and J516‚ define specifications for hydraulic tube and hose fittings. These standards ensure safety‚ durability‚ and compatibility‚ guiding the selection of fittings based on pressure ratings and performance requirements. They cover various fitting types‚ including adapters‚ connectors‚ and flanges‚ ensuring reliable connections in hydraulic systems.

3.2 ISO Standards for Hydraulic Fittings

ISO standards provide global benchmarks for hydraulic fittings‚ ensuring compatibility‚ safety‚ and interchangeability. They define requirements for materials‚ design‚ and performance‚ addressing international market needs. Compliance with ISO standards guarantees reliable operation across diverse applications‚ fostering trust and consistency in hydraulic systems worldwide.

3.3 Identification of Fittings Types and Sizes

Identifying hydraulic fittings involves recognizing their types‚ such as NPT‚ JIC‚ or BSPP‚ through thread patterns and sizes. Charts and guides detail dimensions‚ thread types‚ and pressure ratings‚ ensuring correct selection. Proper identification prevents mismatches‚ enhancing system efficiency and safety‚ while standardized labeling aids in quick recognition and installation by technicians.

Hydraulic Hose Fittings Charts and Size Guides

Charts and guides provide detailed sizing and type information for hydraulic hose fittings‚ ensuring compatibility and performance. They include dash sizes‚ thread types‚ and pressure ratings for accurate selection.

4.1 Dash Size and Thread Type Compatibility

Dash sizes indicate hose fitting diameters‚ while thread types ensure compatibility. Proper matching of dash and thread sizes is crucial for leak-free connections and optimal performance in hydraulic systems.

4.2 Hose and Fittings Size Charts

Hose and fittings size charts provide detailed information on compatible sizes‚ thread types‚ and pressure ratings. These charts help professionals like pipefitters and engineers select the right components for their hydraulic systems‚ ensuring optimal performance and safety. They often include SAE and ISO standards‚ making it easier to match hoses with fittings accurately.

4.3 Diameter and Pressure Ratings

Diameter and pressure ratings are critical for selecting hydraulic fittings. Standards like SAE and EN specify maximum pressure based on fitting size. For example‚ a -8C5 hose has a 13/32″ ID‚ meeting SAE 100R5 standards. Proper matching ensures system efficiency and safety‚ preventing failures under pressure.

Materials and Manufacturing Processes

Hydraulic fittings are made from high-strength materials like steel‚ stainless steel‚ and brass. Advanced manufacturing processes‚ including forging and machining‚ ensure durability and precision in fluid power systems.

5.1 Materials Used for Hydraulic Fittings

Hydraulic fittings are typically made from high-strength materials such as carbon steel‚ stainless steel‚ and brass. These materials offer excellent durability‚ corrosion resistance‚ and ability to withstand high pressures. Some fittings may also use specialized alloys for extreme conditions‚ ensuring reliability in demanding applications while meeting SAE and ISO standards for performance and safety.

5.2 Manufacturing Processes for Hydraulic Fittings

Manufacturing hydraulic fittings involves precision machining‚ forging‚ and casting. Advanced processes like CNC machining ensure tight tolerances and high-quality finishes. Some fittings undergo heat treatment for enhanced strength‚ while others are plated or coated for corrosion resistance‚ ensuring durability and reliability in hydraulic systems.

Applications of Hydraulic Fittings

Hydraulic fittings are used in industrial machinery‚ construction equipment‚ and aerospace systems‚ ensuring reliable fluid power transmission. They are essential for connecting hoses‚ tubes‚ and pipes in high-pressure systems.

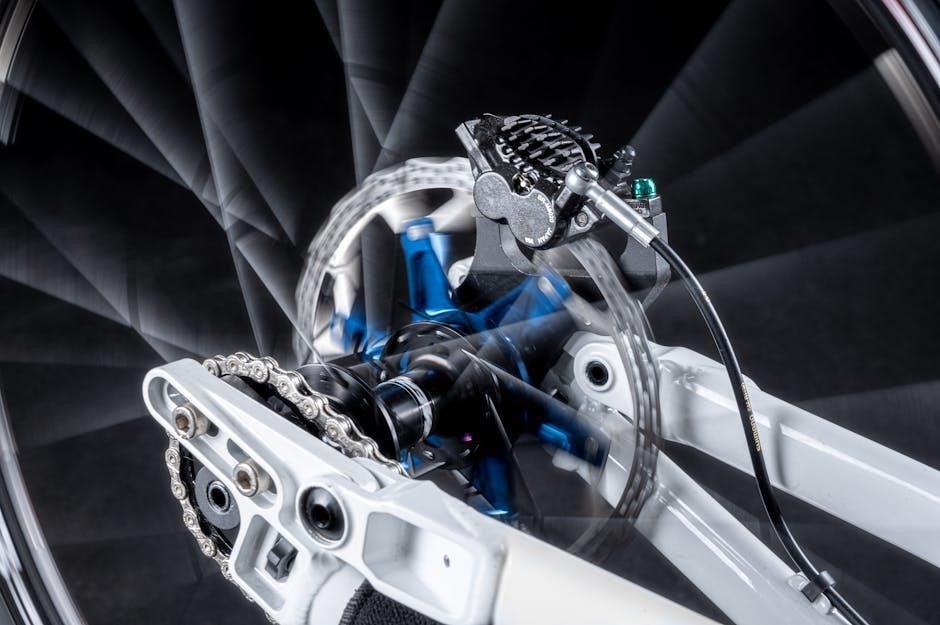

6.1 Industrial and Mobile Hydraulic Systems

In industrial and mobile systems‚ hydraulic fittings connect hoses and tubes‚ enabling efficient fluid power transmission. They are crucial for heavy-duty applications like construction equipment‚ manufacturing machinery‚ and agricultural vehicles‚ ensuring durability and reliability under high pressure and harsh conditions.

6.2 Aerospace and Defense Applications

Hydraulic fittings play a critical role in aerospace and defense systems‚ ensuring precise fluid control in aircraft‚ missiles‚ and military equipment. They meet stringent SAE and ISO standards‚ offering high reliability and durability. Common types like ORFS and JIC fittings are used in fuel systems‚ landing gear‚ and weapon systems‚ where failure is not an option.

Leading Brands and Suppliers

Parker Hannifin and Manuli Hydraulics are prominent brands‚ offering high-quality hydraulic fittings. They provide innovative solutions‚ ensuring reliability and performance across various industrial applications globally.

7.1 Parker Hannifin Corporation

Parker Hannifin is a global leader in hydraulic fittings‚ offering high-performance solutions. Known for innovation‚ they provide a wide range of products‚ including Parkrimp and ParLock hoses. Their commitment to quality and reliability makes them a trusted choice for industrial and mobile applications‚ ensuring optimal performance and durability in demanding environments.

7.2 Manuli Hydraulics

Manuli Hydraulics offers a diverse range of hydraulic fittings‚ including the MF2000‚ MF3000‚ and Smart Connectors. Their products are designed for high performance and durability‚ catering to various industrial applications. Manuli’s commitment to innovation and quality ensures reliability in demanding environments‚ making them a preferred choice for hydraulic systems worldwide.

Safety and Installation Guidelines

Proper installation techniques and safety precautions are crucial when handling hydraulic fittings. Avoid kinking hoses and ensure all connections meet SAE and ISO standards for optimal performance and longevity;

8.1 Proper Installation Techniques

Proper installation ensures system reliability and safety. Always clean threads‚ use torque wrenches for precise tightening‚ and avoid over-tightening to prevent damage. Ensure all connections are compatible and aligned. Never force-fit components‚ as this can compromise integrity. Use recommended sealants and follow manufacturer guidelines for thread preparation and assembly. Regularly inspect for wear or damage before operation.

8.2 Safety Precautions for Handling Hydraulic Fittings

Always wear protective gear‚ including gloves and safety goggles‚ when handling hydraulic fittings. Ensure systems are de-pressurized before servicing. Avoid sudden pressure releases‚ which can cause injury. Use proper tools to prevent damage to fittings or hoses. Never force-fit components‚ as this can lead to system failure. Regularly inspect fittings for wear or damage‚ and always follow manufacturer guidelines and safety protocols.

Hydraulic fittings are crucial for efficient fluid power systems‚ ensuring safe and reliable connections. Proper selection and adherence to standards like SAE and ISO are essential for optimal performance and safety.

9.1 Summary of Key Points

Hydraulic fittings are vital for connecting hoses‚ tubes‚ and pipes in fluid power systems. They come in various types‚ including NPT‚ JIC‚ and BSPP‚ each with specific standards. Proper selection ensures safety and efficiency‚ while adherence to SAE and ISO standards guarantees reliability. Understanding these components is essential for maintaining optimal system performance and preventing failures.

9.2 Importance of Selecting the Right Hydraulic Fittings

Selecting the right hydraulic fittings is essential for system safety and efficiency. Incorrect fittings can cause leaks‚ failures‚ and hazards. Proper selection ensures compatibility‚ maintains flow rates‚ and prevents pressure issues. Adhering to standards like SAE and ISO ensures performance and durability‚ with suitable materials handling high pressures and harsh conditions‚ minimizing maintenance and ensuring compliance with industry specifications.