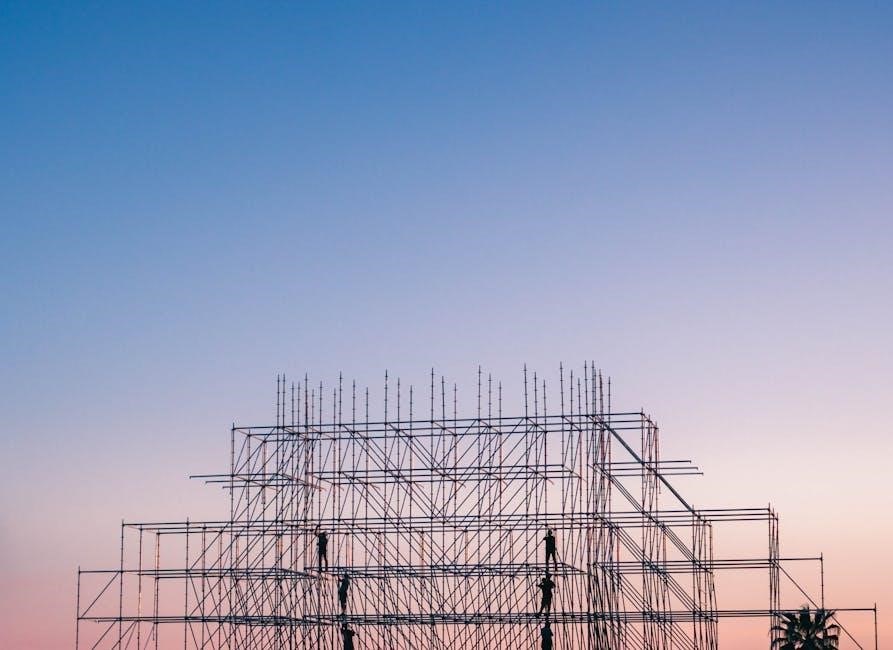

Scaffolding parts are essential components for constructing temporary support structures․ Key elements include frames, tubes, couplers, and accessories, ensuring stability and safety․ Various systems like tube and clamp or frame scaffolding offer flexibility and strength, catering to different construction needs․ Understanding these parts is crucial for safe and efficient building operations․

Overview of Scaffolding Components

Scaffolding components are essential for constructing temporary support structures․ They include frames, tubes, couplers, boards, and accessories like guardrails and base plates․ These parts ensure stability and safety for workers․ Components vary by system, such as tube and clamp or frame scaffolding․ Each part plays a critical role in building, maintenance, or repair projects․ Understanding their functions and proper use is vital for efficient and safe scaffolding operations․ These elements are designed to adapt to different construction needs while maintaining structural integrity and worker safety․

Importance of Scaffolding in Construction

Scaffolding is crucial in construction for enabling safe and efficient work at heights․ It provides sturdy platforms for workers, materials, and equipment, ensuring project efficiency․ Scaffolding systems adapt to various project needs, from renovation to large-scale builds․ They enhance worker safety by reducing risks of falls and injuries․ Properly designed scaffolding also minimizes construction delays and improves overall productivity․ Its versatility and structural integrity make it an indispensable tool in modern construction, supporting timely and secure completion of projects․

Major Scaffolding Parts

Key scaffolding components include frames, tubes, clamps, boards, and couplers․ These parts provide structural support, stability, and safety for workers during construction and maintenance tasks․

Scaffold Frames and Their Types

Scaffold frames are foundational structures that provide stability and support․ They come in various types, including H-frames, ladder frames, and walk-through frames․ H-frames are widely used for their strength and versatility, while ladder frames offer easy mobility․ Walk-through frames feature open sides for convenient access․ These frames are typically made of durable materials like steel or aluminum, ensuring longevity and load-bearing capacity․ Their design allows for easy assembly and adaptation to different construction sites, making them indispensable in scaffolding systems․ Proper selection of frames is crucial for ensuring safety and efficiency in construction projects․

Tubes and Clamps: Key Structural Elements

Tubes and clamps are fundamental components in scaffolding systems, providing the structural framework․ Tubes, typically made of steel or aluminum, serve as the primary building material․ Clamps, such as swivel and fixed couplers, connect tubes at various angles, ensuring stability․ These elements allow for flexible and secure connections, enabling the construction of customized scaffolding configurations․ Their durability and adaptability make them essential for creating safe and reliable work platforms․ Proper use of tubes and clamps ensures the scaffolding system’s structural integrity and safety for workers․

Boards and Transoms for Work Platforms

Boards and transoms are critical for creating stable work platforms in scaffolding systems․ Boards provide the walking and working surface, typically made of durable materials like wood or steel․ Transoms are horizontal beams that support the boards, attaching them securely to the scaffolding frame․ These components ensure a safe and even surface for workers․ Regular inspections are essential to maintain their integrity and prevent hazards․ Proper installation and maintenance of boards and transoms are vital for ensuring worker safety and structural stability in construction projects․

Advanced Scaffolding Components

Advanced scaffolding components enhance structural integrity and adaptability․ These include couplers, beam clamps, and ledger systems, designed to improve efficiency and safety in complex construction projects․

Couplers: Swivel, Fixed, and Double

Couplers are vital connectors in scaffolding systems, ensuring secure joints between tubes․ Swivel couplers allow flexibility, while fixed couplers provide rigid connections․ Double couplers connect multiple tubes, enhancing stability․ They are made from durable materials, meeting safety standards to withstand heavy loads․ Proper use of couplers is critical for maintaining structural integrity and preventing accidents; Their versatility makes them indispensable in various scaffolding configurations, ensuring reliable support for workers and materials․

Beam Clamps and Ledger Systems

Beam clamps and ledger systems are crucial for securing scaffolding structures․ Beam clamps, also known as girder couplers, attach scaffolding to beams, ensuring stability․ Ledger systems consist of horizontal tubes supported by ledgers, forming the scaffold’s framework․ These components are designed to handle heavy loads safely․ Their durable construction and precise engineering ensure reliability in various construction environments, making them essential for large-scale projects requiring robust support systems․

Side Brackets and Ladders for Access

Side brackets and ladders provide efficient access to scaffolding platforms․ Side brackets extend the scaffold’s width, offering additional workspace, while ladders ensure safe ascent and descent․ These components are designed for durability and ease of use, making them indispensable for workers needing reliable access to elevated areas․ Their versatility allows integration into various scaffolding systems, enhancing overall functionality and safety in construction settings․

Specialized Scaffolding Systems

Specialized scaffolding systems offer tailored solutions for unique construction challenges․ These systems are modular, flexible, and designed for specific tasks, ensuring efficiency and safety in complex projects․

Tube and Clamp Scaffolding: Flexibility and Strength

Tube and clamp scaffolding is renowned for its adaptability and durability․ Comprising steel tubes connected by clamps, it allows for versatile configurations, making it ideal for irregular structures․ This system offers excellent load-bearing capacity and is easy to assemble, ensuring both strength and flexibility․ Its modular design enables it to be tailored to various project requirements, providing a reliable and efficient solution for complex construction tasks․ This scaffolding type is widely used in industries requiring customized support systems․

Frame Scaffolding: Ease of Assembly and Use

Frame scaffolding is highly regarded for its simplicity and efficiency․ Pre-fabricated frames with built-in side brackets simplify assembly, reducing time and labor․ These frames are lightweight yet durable, making them easy to transport and install․ Designed for quick setup, they often feature snap-on clamps or couplers, ensuring a secure connection․ The modular design allows for easy expansion, catering to various project scales․ Frame scaffolding is ideal for straightforward applications, offering a practical solution for contractors seeking a balance of convenience and reliability․

Cup Lock Scaffolding: Modular and Efficient

Cup lock scaffolding is a modular system known for its versatility and ease of use․ The unique cup and lock mechanism allows for quick assembly and disassembly, with minimal tools required․ Its robust design ensures stability and supports heavy loads, making it ideal for large-scale projects․ The system’s modularity enables adaptation to complex structures, while its lightweight components enhance portability․ Widely used in construction, maintenance, and renovation, cup lock scaffolding offers durability and cost-effectiveness, making it a preferred choice for contractors seeking efficient solutions․

Scaffolding Accessories

Scaffolding accessories include essential components for safety and structural integrity, such as guardrails, base plates, stairways, and ladders, ensuring secure and efficient construction operations․

Guardrails and Safety Nets

Guardrails and safety nets are vital scaffolding accessories that prevent falls and protect workers․ Guardrails are installed along platform edges to create a barrier, while safety nets catch falling debris, ensuring a safer environment․ These components must meet safety standards and are often used together for maximum protection․ Proper installation and regular inspection are crucial to maintain their effectiveness and compliance with safety regulations․

Stairways and Platforms for Safe Access

Stairways and platforms are essential for safe access in scaffolding systems․ They provide efficient pathways for workers and materials, reducing risks of accidents․ Stairways often include handrails and landings, while platforms offer stable work areas․ These components are designed to meet safety standards, ensuring durability and reliability․ Proper assembly and regular inspections are critical to maintain their structural integrity and ensure safe operation․

Base Plates and Jacks for Stability

Base plates and jacks are critical for ensuring scaffolding stability․ They distribute the structure’s weight evenly, preventing movement or collapse․ Base plates provide a solid foundation, while jacks adjust the scaffold’s height and level․ These components are made from durable materials to withstand heavy loads and harsh conditions․ Proper installation and regular checks are essential to maintain stability and ensure worker safety․

Scaffolding Standards and Specifications

Scaffolding must comply with safety codes and load-bearing capacities․ Standards ensure durability and reliability, guaranteeing worker safety and structural integrity during construction projects․

Load Capacity and Safety Ratings

Load capacity and safety ratings are critical for scaffolding systems․ Components like couplers and beam clamps have specified safe working loads, such as 6․1kN for swivel couplers and 9․1kN for others․ These ratings ensure structural integrity and prevent collapse․ Exceeding these limits can lead to accidents․ Compliance with standards like EN74 and AS/NZS 1576․1 is mandatory․ Regular inspections and maintenance are essential to uphold these safety benchmarks, ensuring reliable performance under expected loads․

Material Quality and Durability

Material quality is paramount for scaffolding durability․ High-strength steel and aluminum alloys are commonly used, offering exceptional resistance to corrosion and wear․ Components like tubes, clamps, and frames are engineered to withstand harsh conditions․ Durable materials ensure longevity, reducing the need for frequent replacements․ Proper manufacturing processes and rigorous testing guarantee scaffolding parts meet safety and performance standards, providing reliable support in demanding environments․ Quality materials are essential for maintaining structural integrity and ensuring worker safety over time․

Compliance with Building Codes

Adhering to building codes ensures scaffolding structures meet legal and safety requirements․ Local and federal regulations dictate specific standards for scaffolding design, load capacity, and installation․ Compliance involves using approved materials, following assembly guidelines, and conducting regular inspections․ Non-compliance can lead to safety risks and legal penalties; Scaffolding components must be certified to meet these standards, guaranteeing reliability and safety․ Proper documentation and adherence to codes are essential for maintaining safe working conditions and avoiding regulatory issues during construction projects․

Maintenance and Inspection

Regular inspections ensure scaffolding safety and durability․ Components must be checked daily by a competent person for damage or wear, adhering to federal and local guidelines․

Regular Checks for Safe Operation

Regular checks are essential for ensuring scaffolding safety․ A competent person must inspect all components daily before use, focusing on damage, wear, and proper assembly․ Couplers, tubes, and frames should be examined for integrity, while boards and transoms must be securely fastened․ Any damaged or loose parts must be repaired or replaced immediately․ Proper alignment and stability of the structure are critical to prevent accidents․ Compliance with safety standards and manufacturer guidelines ensures reliable operation and protects workers from potential hazards․ Regular maintenance also extends the lifespan of scaffolding equipment․

Repair and Replacement Guidelines

Repair and replacement of scaffolding parts must adhere to strict guidelines to ensure safety․ Damaged components like tubes, couplers, or boards should be replaced immediately if they cannot be repaired․ Repairs must be conducted by qualified personnel using approved methods and materials․ All replacements should meet original equipment specifications to maintain structural integrity․ Regular maintenance records should be kept to track the condition of scaffolding components․ Following manufacturer instructions is crucial to uphold safety standards and prevent potential failures during operation․ Proper disposal of damaged parts is also recommended to avoid misuse․

Storage and Handling Best Practices

Proper storage and handling of scaffolding parts are crucial for maintaining their integrity․ Components should be stored in a clean, dry environment, protected from damage and corrosion․ Use protective covers for tubes and clamps to prevent rust․ Handle parts with care to avoid bending or denting․ Store scaffolding on flat, stable surfaces, ensuring all pieces are secure․ Follow manufacturer guidelines for stacking heights and weights․ Regularly inspect stored components for damage before reuse․ Organize parts to prevent mixing or misplacement, ensuring easy access for future projects․ Proper storage and handling extend the lifespan of scaffolding equipment․