Manual water pumps must meet specific requirements, including proper material durability, resistance to corrosion, and compatibility with water types. They should be designed for safe operation, ensuring reliable water extraction while adhering to safety standards and regulations.

1.1 Definition and Purpose

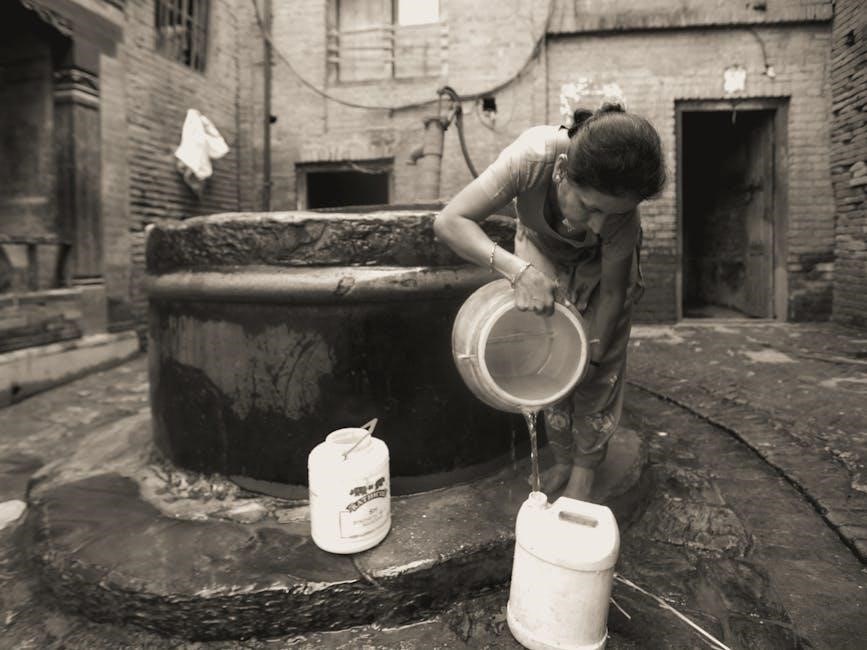

A manual water pump is a device operated by hand to extract water from a source, such as wells, reservoirs, or surface water. Its primary purpose is to provide a reliable, portable, and energy-free solution for accessing water in various settings, including domestic, agricultural, and emergency situations. It ensures consistent water supply with minimal effort and simplicity.

1.2 Importance in Water Supply Systems

Manual water pumps are essential for reliable water access in remote or off-grid areas, ensuring consistent supply during power outages or emergencies. They provide a sustainable, eco-friendly solution for domestic and agricultural needs, promoting water conservation and self-sufficiency. Their simplicity and durability make them a critical component in basic water supply systems worldwide.

Types of Manual Water Pumps

Manual water pumps are categorized into lever-action, rotary, and diaphragm types, each designed for specific applications. These designs ensure efficient water extraction in various settings.

2.1 Lever-Action Pumps

Lever-action pumps require a robust construction to handle repetitive motion. They must be made from durable, corrosion-resistant materials. These pumps are designed for ease of operation, ensuring smooth water extraction. Proper installation and regular maintenance are essential to maintain efficiency and longevity. They are ideal for applications where simplicity and reliability are key.

2.2 Rotary Pumps

Rotary pumps require precise engineering to ensure smooth operation. They must have a durable rotor and stator design. These pumps are known for high efficiency and consistent flow rates. Proper sealing and alignment are crucial to prevent leaks and wear. Regular lubrication and inspection are necessary to maintain performance and extend lifespan. They are suitable for demanding applications.

2.3 Diaphragm Pumps

Diaphragm pumps require a flexible and durable diaphragm material to handle various fluids. They must have a robust check valve system to ensure unidirectional flow. These pumps are ideal for applications requiring low maintenance and resistance to abrasives. Proper installation and regular inspection of the diaphragm and valves are essential to maintain efficiency and prevent failure over time.

Safety Requirements

Manual water pumps must comply with safety standards to prevent overpressure and ensure safe operation. Proper flushing and rinsing of components are crucial to maintain hygiene and functionality.

3.1 General Safety Guidelines

Manual water pumps must be operated with caution. They should be thoroughly flushed with clean water before use and regularly inspected for wear and tear. Avoid using them for saltwater, sewage, or corrosive liquids. Proper installation and maintenance are essential to prevent overpressure and ensure safe operation. Always follow manufacturer guidelines to maintain efficiency and prevent potential hazards.

3.2 Marine-Specific Safety Regulations

Marine manual water pumps must comply with stringent regulations. Sailboats and powerboats between 9 to 12 meters require a manual bilge pump on board. The pump must handle water effectively, with larger vessels needing higher capacity systems. Compliance ensures safety, preventing water accumulation that could lead to capsizing. Regular inspections and adherence to marine standards are mandatory for reliable operation.

Installation and Maintenance

Proper installation ensures optimal pump performance. Regular maintenance involves flushing with clean water and inspecting components. This extends lifespan and ensures reliable operation over time.

4.1 Installation Considerations

Proper installation is crucial for manual water pumps to ensure efficiency and longevity. The pump must be placed in an accessible location, protected from contaminants, and aligned with the water source. Ensure all connections are secure and sealed to prevent leaks. Following the manufacturer’s guidelines is essential for optimal performance and safety. Regular checks are recommended.

4.2 Maintenance Best Practices

Regular maintenance is essential to ensure the durability and efficiency of manual water pumps. This includes cleaning or replacing worn-out parts, lubricating moving components, and checking for leaks. Flushing the pump with clean water after dismantling prevents contamination. Adhering to the manufacturer’s maintenance schedule ensures optimal performance and extends the pump’s lifespan. Always follow safety guidelines during maintenance.

Capacity and Flow Rate Requirements

Manual water pumps must meet specific capacity and flow rate requirements to ensure efficient water extraction. Proper sizing is crucial to handle the intended water volume effectively.

5.1 Determining Pump Capacity

Determining the required capacity of a manual water pump involves assessing the water source, intended use, and flow rate needs. The pump’s capacity must match the volume of water to be extracted. Proper sizing ensures efficient operation and minimizes wear. Factors like head pressure and suction lift also influence capacity calculations. Always consider the minimum efficiency index (MEI) for optimal performance and reliability.

5.2 Flow Rate and Efficiency

The flow rate of a manual water pump is critical for meeting water supply demands. Efficiency is measured by the pump’s ability to convert manual effort into water delivery. Factors such as pump design, material quality, and maintenance significantly impact performance. Ensuring optimal flow rate and efficiency requires selecting the right pump size and adhering to minimum efficiency index (MEI) standards. Regular maintenance also plays a key role in sustaining performance.

Efficiency and Performance

Manual water pumps must be designed for maximum efficiency, ensuring reliable operation and minimal effort. Proper maintenance and optimal design are crucial for meeting performance requirements effectively.

6.1 Maximizing Pump Efficiency

To maximize efficiency, manual water pumps must be regularly maintained, ensuring all moving parts are clean and well-lubricated. Using materials resistant to corrosion and wear extends lifespan. Proper pump sizing for the intended application is crucial to avoid underperformance or overexertion. Smooth operation and minimal mechanical strain ensure optimal water flow and energy conservation, aligning with performance standards.

6.2 Performance Metrics

Performance metrics for manual water pumps include flow rate, pressure output, and efficiency. Proper installation and maintenance ensure optimal metrics, while adhering to safety standards prevents overpressure risks. Regular flushing and inspections enhance performance, ensuring reliable operation across various applications. Compliance with regulations guarantees pumps meet required standards for both domestic and marine uses.

Applications of Manual Water Pumps

Manual water pumps are essential for domestic, agricultural, and marine use. They provide reliable water extraction in emergencies and remote areas, ensuring safety and efficiency always.

7.1 Domestic Use

Manual water pumps are vital for domestic water supply, especially in rural or off-grid homes. They provide a reliable means of accessing clean water for drinking, cooking, and hygiene. Easy to install and maintain, these pumps ensure consistent water flow, making them an essential tool for daily household needs and emergency preparedness. Their durability and simplicity make them ideal for long-term use.

7.2 Agricultural Use

Manual water pumps are crucial for agricultural irrigation, enabling farmers to supply water to crops efficiently. They are often used in remote areas where electricity is unavailable, ensuring consistent water flow for livestock and field irrigation. Durable and low-maintenance, these pumps support sustainable farming practices, helping to meet the water needs of both small and large agricultural operations effectively.

7.3 Emergency and Marine Applications

Manual water pumps are essential in emergency and marine applications, often required on boats to remove bilge water. Sailboats and powerboats between 9 to 12 meters must carry them to ensure safety. They are also vital for emergency water supply in disaster scenarios, providing a reliable means to access clean water when other systems fail.

Regulations and Compliance

Manual water pumps must comply with marine and safety regulations, ensuring they meet specific standards for vessel size requirements and operational safety. Regular inspections are mandatory to maintain compliance.

8.1 Marine Regulations

Manual water pumps on marine vessels must comply with specific regulations, ensuring safety and efficiency. Sailboats and powerboats between 9 to 12 meters require a manual bilge pump for emergency water removal. These pumps must meet marine safety standards, including capacity requirements and operational reliability. Regular inspections are mandatory to ensure compliance with Small Vessel Regulations and maintain seaworthiness.

8.2 Compliance Standards

Manual water pumps must meet specific compliance standards to ensure safety and performance. Pumps should be designed to handle clean water without abrasive particles, adhering to efficiency standards like the Minimum Efficiency Index. They must not be used for hazardous liquids. Proper installation and maintenance are crucial to meet operational regulations and ensure reliability in various applications.

Troubleshooting and Repair

Regular troubleshooting is essential to identify issues like clogged filters or worn seals. Repair involves dismantling the pump, cleaning parts, and replacing damaged components to restore functionality.

9.1 Common Issues

Manual water pumps often face issues like corrosion, worn-out seals, and clogged intake valves. Regular flushing with clean water and inspecting for damage can prevent these problems. Ensuring the pump is not used for corrosive or explosive liquids is crucial to maintain longevity and efficiency. Proper storage and maintenance can also minimize common issues.

9.2 Repair and Maintenance Tips

Regularly inspect and clean the pump to prevent clogging. Lubricate moving parts and replace worn-out seals or gaskets. After dismantling, rinse components in clean water. Ensure the pump is stored in a dry place to avoid corrosion. Always follow the manufacturer’s instructions for repairs and maintenance to maintain efficiency and extend the pump’s lifespan.

Manual water pumps are essential for reliable water supply, requiring proper installation, maintenance, and adherence to safety standards to ensure efficient and long-lasting performance.

10.1 Summary of Key Requirements

Manual water pumps must meet durability, safety, and efficiency standards. They should be constructed from corrosion-resistant materials and designed for compatibility with diverse water types. Proper installation, regular maintenance, and adherence to safety regulations are crucial. Ensuring adequate flow rate and capacity is essential for reliable operation across various applications, including domestic, agricultural, and marine environments.

10.2 Future Trends

Future trends for manual water pumps include integrating advanced materials for durability and lightweight designs. Innovations in efficiency, such as variable flow mechanisms, are expected to enhance performance. Additionally, eco-friendly and energy-efficient technologies will likely dominate, reducing environmental impact while maintaining reliability across domestic, agricultural, and marine applications. These advancements aim to meet growing demands for sustainable water solutions globally.